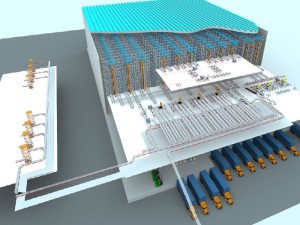

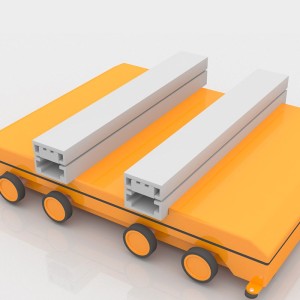

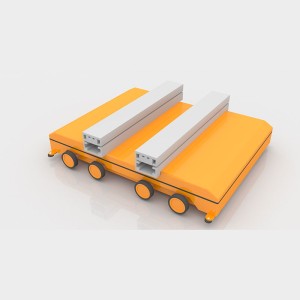

Application method: run along the track in the roadway of the high-rise shelf warehouse, access the unit goods to the cargo compartment, and complete the in-out operation.

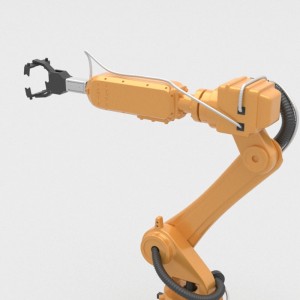

Stacker

描述

Descripition

Specification

Solutions

Case

Application Method:

run along the track in the roadway of the high-rise shelf warehouse, access the unit goods to the cargo compartment, and complete the in-out operation.

| Specification | |

|

Ambient temperature |

-40~-20℃ -20~40℃ |

|

Running speed |

~240m/min |

|

Acceleration rate |

0~0.5m/s2 |

|

Equipment height |

45m |

|

Cargo weight |

~2500KG |

Warehouse Automation System Solutions

With the rapid development of the enterprise, the variety of products, and the accelerated turnover of material storage, the logistics and storage space of the enterprise is beginning to be tight. Therefore, various material storage projects have become an inevitable measure for enterprises to improve efficiency and core competitiveness. PGSL merged into the airport logistics sector of CIMC Group through reverse acquisition, integrated CIMC Group’s warehousing project resources and products, and provided customers with a package of logistics and warehousing solutions.

Home Industry

-Overcoming the difficulties of automatic sorting in the home industry, realizing automatic sorting and direct loading.

-Realizing the fully automatic connection between the 5 workshops and automated warehouses.

-Realizing the off-site loading of products with various specifications, such as sofas, mattresses, and panel furniture.

-WMS: Customized the link management between multiple warehouses and locations (five logistics centers and 35 subsidiary warehouses).

East China Medicine

-Equipped with air shower system, automatic labeling system, automatic online weighing, automatic glue spraying system (to ensure the stability of the stacking type), automatic palletizing system.

-Automatic depalletizing and sorting of bagged raw materials and put them directly into the fermentation tank with review systems configured to ensure the accuracy of the materials).

-The AGV system is used to realize the distribution of raw and auxiliary materials to each station in the workshop and the recovery of empty pallets.

-Only 4 robots are used to realize the palletizing technology of 26 production lines at the same time (a palletizing buffer pool is built).